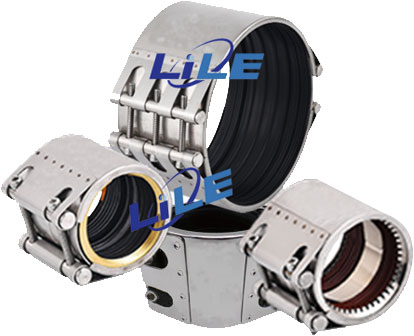

Category:Auxiliary accessories

Introduction:

Stainless steel pipeline quick connector and quick repair is widely used in petroleum, chemical, light industry, medicine, food, construction, municipal and other industries of all kinds of material pipe connection, suitable for pipe diameter from 20mm to 1000mm all material pipe connection, stable and reliable products.Stainless steel pipeline quick connector and quick repair is widely used in petroleum, chemical, light industry, medicine, food, construction, municipal and other industries of all kinds of material pipe connection, suitable for pipe diameter from 20mm to 1000mm all material pipe connection, stable and reliable products.

Product reference standard

Din 86128-1 and DIN86128-2 Connectors for pipelines (German standard)

Flexible connectors for pipes CB/T4176-2013

Component Name | Material is qualitative |

Shell | S30408,S30403,S20608,S30603,S220503 |

Seal ring material | Ethylene propylene diene diene (EPDM), Nitrile (NBR) silicone rubber (MVQ), fluorine rubber (VITON A) |

Fasteners (bolts, pins) | Anti-corrosion dacro treatment, stainless steel, etc |

Technical characteristics

Type GKL-A is A universal connector

Gkl-b has strong pull - out resistance and good sealing performance.

Gkl-c type can be used for non-metallic pipe or metal to non-metallic pipe connection, axial anti-pulling, unique barb type copper ring design, enhance corrosion resistance, improve the protection performance of non-metallic pipe.

Gkx-a hinge type, GKX-B double card type can be used for the connection of new pipelines, but also for pipeline leakage, damage repair, can be in the case of non-stop pressure, without replacing the pipeline to aging, corroded pipeline trachoma, fracture and other conditions for rapid repair.

Applications

Stainless steel pipe fast connector has strong universality, it can be applied to all kinds of metal pipe or non-metal pipe fast connection; There are no special requirements for the fluid medium in the pipe, the thickness of the pipe wall and the end face. It can replace the tedious connection methods such as flange or welding, and can solve the connection of different pipe diameters, axial displacement, Angle deviation and different pipes.

Note: Support rings must be used for piping made of soft thermoplastic materials such as PE. A support ring is placed at the end of the two connected pipes to prevent excessive deformation of the pipe.

Specification and size

Gkl-a gkl-b pipeline quick connector is applicable to 30-377mm pipeline

Pipe OD øA(mm) | Scope of use(mm) | Working pressure PN(Mp) | Pipe spacing Cmax(mm) | Size | Bolt specification(M) | Installation torque(Nm) | ||

B(mm) | D(mm) | E(mm) | ||||||

30 | 29.5-30.5 | 32 | 5 | 62 | 47 | 75 | 8 | 10 |

42 | 42-44 | 32 | 5 | 62 | 65 | 95 | 8 | 15 |

44.5 | 44-45.1 | 32 | 5 | 62 | 65 | 95 | 8 | 15 |

48.6 | 47-49 | 32 | 5 | 62 | 70 | 100 | 8 | 15 |

54 | 53.5-54.8 | 32 | 5 | 75 | 76 | 105 | 8 | 20 |

57 | 56.3-57.6 | 32 | 5 | 75 | 76 | 105 | 8 | 20 |

60.3 | 59-62 | 32 | 5 | 80 | 85 | 105 | 8 | 20 |

63 | 62.2-63.8 | 28 | 5 | 80 | 85 | 105 | 8 | 20 |

76.1 | 75.3-78 | 28 | 5 | 80 | 100 | 120 | 8 | 20 |

80 | 78.9-80.8 | 28 | 5 | 80 | 100 | 120 | 8 | 20 |

89 | 88-92 | 28 | 5 | 107 | 110 | 130 | 10 | 30 |

110 | 108.9-111.2 | 28 | 5 | 107 | 130 | 150 | 10 | 30 |

114.3 | 112-116 | 28 | 5 | 107 | 135 | 155 | 10 | 30 |

125 | 123.6-126.5 | 28 | 5 | 107 | 150 | 185 | 10 | 30 |

133 | 131.5-134.5 | 24 | 5 | 107 | 160 | 190 | 10 | 30 |

140 | 138-142 | 24 | 5 | 116 | 165 | 195 | 12 | 50 |

159 | 157-161 | 24 | 5 | 116 | 185 | 215 | 12 | 50 |

170 | 168.5-171.5 | 24 | 5 | 116 | 195 | 225 | 12 | 50 |

200 | 198.2-201.5 | 24 | 10 | 155 | 240 | 270 | 14 | 80 |

219 | 217-221 | 24 | 10 | 155 | 250 | 290 | 14 | 80 |

250 | 250-254 | 12 | 10 | 155 | 285 | 315 | 14 | 80 |

273 | 271-275 | 12 | 10 | 155 | 305 | 335 | 14 | 80 |

315 | 313-317 | 12 | 10 | 155 | 340 | 375 | 14 | 100 |

355 | 354-357 | 12 | 10 | 155 | 385 | 420 | 14 | 100 |

377 | 375-379 | 12 | 10 | 155 | 410 | 440 | 14 | 100 |

Gkl-c Non-metallic Pipe quick connector is suitable for pipe range 63-800mm

Pipe OD øA(mm) | Scope of use(mm) | Working pressure PN(Mp) | Pipe spacing Cmax(mm) | Size | Bolt specification(M) | Installation torque(Nm) | ||

B(mm) | D(mm) | E(mm) | ||||||

63 | 62-63.8 | 20 | 10 | 75 | 85 | 105 | 8 | 25 |

75 | 74-76 | 20 | 25 | 105 | 100 | 120 | 8 | 30 |

90 | 88-91 | 20 | 25 | 105 | 110 | 130 | 8 | 40 |

110 | 108-111 | 20 | 25 | 120 | 130 | 150 | 10 | 40 |

125 | 123-126 | 20 | 25 | 120 | 145 | 165 | 10 | 40 |

140 | 138-142 | 20 | 30 | 120 | 160 | 180 | 10 | 40 |

160 | 158-162 | 20 | 30 | 120 | 180 | 200 | 10 | 40 |

180 | 178-182 | 16 | 35 | 152 | 210 | 240 | 12 | 50 |

200 | 198-202 | 16 | 35 | 152 | 230 | 260 | 12 | 50 |

225 | 223-226 | 16 | 35 | 152 | 255 | 285 | 12 | 50 |

250 | 248-252 | 16 | 35 | 152 | 280 | 310 | 12 | 50 |

280 | 278-282 | 16 | 35 | 152 | 310 | 345 | 12 | 50 |

315 | 313-317 | 16 | 35 | 152 | 345 | 375 | 12 | 60 |

355 | 353-357 | 12 | 35 | 152 | 385 | 415 | 12 | 60 |

400 | 398-402 | 12 | 35 | 152 | 430 | 460 | 12 | 60 |

450 | 447-453 | 12 | 35 | 152 | 480 | 510 | 12 | 60 |

500 | 497-503 | 10 | 35 | 152 | 530 | 560 | 12 | 60 |

560 | 557-563 | 10 | 35 | 152 | 590 | 620 | 12 | 60 |

630 | 627-633 | 10 | 35 | 152 | 660 | 690 | 16 | 80 |

800 | 786-604 | 10 | 35 | 152 | 830 | 860 | 16 | 80 |

Gkx-a hinge type

Application scope of gkx-a# pipeline quick repair device 32-377mm

Pipe OD øA(mm) | Scope of use(mm) | Working pressure PN(Mp) | Pipe spacingCmax(mm) | Size | Bolt specification(M) | Installation torque(Nm) | ||

B(mm) | D(mm) | E(mm) | ||||||

32 | 31.5-32.5 | 32 | 5 | 62 | 55 | 75 | 8 | 10 |

34 | 33-35 | 32 | 5 | 62 | 55 | 75 | 75 | 10 |

40 | 38.5-41.5 | 32 | 5 | 62 | 55 | 75 | 75 | 10 |

42 | 42-44 | 32 | 5 | 62 | 65 | 95 | 8 | 15 |

44.5 | 44-45.2 | 32 | 5 | 62 | 65 | 95 | 8 | 15 |

48.6 | 47-49 | 32 | 5 | 62 | 70 | 100 | 8 | 15 |

54 | 53.5-54.8 | 32 | 5 | 75 | 76 | 105 | 8 | 20 |

57 | 56.3-57.6 | 32 | 5 | 75 | 76 | 105 | 8 | 20 |

60.3 | 59-62 | 32 | 5 | 80 | 85 | 105 | 8 | 20 |

63 | 62.2-63.8 | 28 | 5 | 80 | 85 | 105 | 8 | 20 |

76.1 | 75.3-78 | 28 | 5 | 80 | 100 | 120 | 8 | 20 |

80 | 78.9-80.8 | 28 | 5 | 80 | 100 | 120 | 8 | 20 |

89 | 88-92 | 28 | 5 | 107 | 110 | 130 | 10 | 30 |

110 | 108.9-111.2 | 28 | 5 | 107 | 130 | 150 | 10 | 30 |

114.3 | 112-116 | 24 | 5 | 107 | 135 | 155 | 10 | 30 |

125 | 123.6-126.5 | 24 | 5 | 107 | 150 | 185 | 10 | 30 |

133 | 131.5-134.5 | 24 | 5 | 107 | 160 | 190 | 10 | 30 |

140 | 138-142 | 24 | 5 | 116 | 165 | 195 | 12 | 50 |

159 | 157-161 | 24 | 5 | 116 | 185 | 215 | 12 | 50 |

170 | 168.5-171.5 | 12 | 5 | 116 | 195 | 225 | 12 | 50 |

200 | 198.2-201.5 | 12 | 10 | 155 | 240 | 270 | 14 | 80 |

219 | 217-221 | 12 | 10 | 155 | 250 | 290 | 14 | 80 |

250 | 250-254 | 12 | 10 | 155 | 285 | 315 | 14 | 80 |

273 | 271-275 | 12 | 10 | 155 | 305 | 335 | 14 | 80 |

315 | 313-317 | 12 | 10 | 155 | 340 | 375 | 14 | 100 |

355 | 354-357 | 12 | 10 | 155 | 385 | 420 | 14 | 100 |

377 | 375-379 | 12 | 10 | 155 | 410 | 440 | 14 | 100 |

Gkx-b double card type

Application scope of gkx-b pipeline quick repair device 159-1219mm

Pipe OD øA(mm) | Scope of use(mm) | Working pressurePN(Mp) | Pipe spacing Cmax(mm) | Size | Bolt specification(M) | Installation torque(Nm) | ||

B(mm) | D(mm) | E(mm) | ||||||

159 | 157-161 | 20 | 10 | 116 | 185 | 210 | 10 | 60 |

170 | 168.5-172 | 20 | 10 | 116 | 195 | 220 | 10 | 60 |

180 | 178-182 | 20 | 10 | 155 | 205 | 230 | 12 | 60 |

200 | 198.2-201.5 | 20 | 15 | 155 | 225 | 260 | 12 | 60 |

219 | 217-221 | 20 | 15 | 155 | 250 | 280 | 12 | 70 |

250 | 248-253 | 20 | 15 | 155 | 280 | 310 | 12 | 70 |

273 | 271-275 | 16 | 15 | 155 | 305 | 335 | 12 | 70 |

315 | 313-317 | 16 | 15 | 155 | 340 | 370 | 12 | 70 |

355.6 | 354-358 | 16 | 15 | 155 | 385 | 415 | 12 | 70 |

377 | 375-379 | 16 | 15 | 155 | 430 | 460 | 12 | 70 |

400 | 398-402 | 16 | 15 | 155 | 435 | 470 | 12 | 70 |

429 | 427-431 | 16 | 15 | 155 | 460 | 490 | 12 | 70 |

480 | 478-482 | 16 | 15 | 155 | 510 | 540 | 12 | 70 |

500 | 498-502 | 16 | 15 | 155 | 530 | 560 | 12 | 80 |

508 | 506-510 | 16 | 15 | 155 | 540 | 570 | 12 | 80 |

530 | 528-532 | 16 | 15 | 155 | 565 | 595 | 12 | 80 |

558.8 | 556-562 | 16 | 15 | 155 | 590 | 620 | 16 | 80 |

609.6 | 608-612 | 16 | 15 | 155 | 640 | 670 | 16 | 80 |

630 | 628-632 | 16 | 15 | 155 | 670 | 700 | 16 | 80 |

711.2 | 708-713 | 16 | 15 | 155 | 745 | 775 | 16 | 80 |

762 | 760-765 | 16 | 15 | 155 | 795 | 835 | 16 | 80 |

812.8 | 811-815 | 16 | 15 | 155 | 845 | 885 | 16 | 100 |

914.4 | 912-918 | 16 | 15 | 155 | 945 | 985 | 16 | 100 |

1016 | 1013-1020 | 10 | 15 | 155 | 1050 | 1090 | 16 | 100 |

1048 | 1045-1052 | 10 | 15 | 155 | 1090 | 1140 | 16 | 100 |

1219 | 1216-1224 | 10 | 15 | 155 | 1255 | 1300 | 16 | 100 |

Wechat QR code

Wechat QR code

Home

Home Tel

Tel Product

Product