Category:Industrial pipeline

Introduction:

Since PE pipes have certain defects in high temperature resistance, it is known from previous engineering cases that if ordinary HDPE lined pipes are used for a long time under the conditions of above 60 ℃, the lining pipes are easy to become soft, the top collapses, and even the pipelines are blocked. In the field of high-temperature transportation, especially in the field of high-temperature oil and gas transportation, the application of pipeline repair is greatly limited. Due to the special flaky crystal structure, the raw material of HTPO pipe has excellent high temperature resistance, stress crack resistance and corrosion resistance, and maintains the pressure bearing capacity and excellent welding performance of ordinary PE pipes.In the mid-to-late 1980s, trenchless pipeline construction technology was introduced into my country, and it has become increasingly popular due to its advantages of simple construction and less damage to the surrounding environment. Existing old pipelines in my country are very serious due to corrosion, leakage and leakage. If they are all replaced, a large amount of investment is required. Maintenance and repair other than excavation is a construction method that is in line with my country's national conditions. According to market demand, especially in the field of oil and natural gas transportation, our company has successfully developed a series of lining repair pipes and matching pipe fittings for trenchless technology.

Introduction of HTPO high temperature resistant lined pipe:

Because PE pipes have certain defects in high temperature resistance, it is known from previous engineering cases that if ordinary HDPE lined pipes are used for a long time under the conditions of above 60 ℃, the lining pipes are easy to become soft, the top collapses, and even the pipelines are blocked. Therefore, in the field of high-temperature transportation, especially in the field of high-temperature oil and gas transportation, the application of pipeline repair is greatly limited.

Due to the special flaky crystal structure, the HTPO pipe raw material has excellent high temperature resistance, stress crack resistance, corrosion resistance, and maintains the pressure bearing capacity and excellent welding performance of ordinary PE pipes.

The strength index of HTPO pipe is close to that of PE pipe, but the difference is that it still has higher strength under high temperature conditions. The long-term service temperature is 75 °C, and the short-term high temperature can reach 85 °C.

Predicted strength reference curve of HTPO liner material. It can be seen from the curve that the hydraulic strength of HTPO liner material has no inflection point under long-term high temperature use conditions.

Introduction of HBPE high barrier liner:

Oil and natural gas are mixtures containing non-hydrocarbon nitrogen, sulfur, oxygen, carbon compounds and a portion of water in addition to mainly hydrocarbon organics. We know that PE has a good barrier to water, and the gas in the pipeline shows relative permeability in PE. In the long-distance transportation of ordinary PE liner, the PE pipe wall is thickened by 8%, and the pipe wall structure is damaged. Airbags are easily formed between the steel pipe and the PE pipe, the diameter of the pipe becomes smaller, which affects the transportation efficiency, and corrodes the outer wall of the steel pipe, wastes energy, and at the same time, it also seriously pollutes our living environment. Under the situation of increasingly scarce resources and increasingly severe environmental protection situation, it is inevitable to develop a high-barrier lined pipe.

The high-barrier lined pipe is a multi-layer pipe, extruded by a co-extruder. The barrier layer adopts a new type of imported barrier material in the world, which is a crystalline polymer with a chain molecular structure. The PE layer or the temperature-resistant layer has excellent water resistance. The combination of the two can solve the problems of efficiency, service life and environmental pollution in the long-distance transportation of oil and natural gas.

Nominal diameter dn | Outer diameter deviation | Single layer tube | Multilayer tube | ||

Nominal wall thickness en | Nominal deviation | Nominal wall thickness en | Nominal deviation | ||

100 | +1.0 | 4.0 | +0.5 | 6.0 | +0.7 |

150 | +1.5 | 5.0 | +0.6 | 7.0 | +0.8 |

195 | +1.9 | 6.0 | +0.7 | 8.0 | +0.9 |

200 | +2.0 | 6.0 | +0.7 | 8.0 | +0.9 |

250 | +2.5 | 7.0 | +0.8 | 9.0 | +1.0 |

300 | +3.0 | 8.0 | +0.9 | 12.0 | +1.3 |

350 | +3.5 | 8.5 | +1.0 | 12.5 | +1.4 |

400 | +4.0 | 9.6 | +1.1 | 13.6 | +1.5 |

500 | +5.0 | 12.5 | +1.4 | 14.5 | +1.6 |

600 | +6.0 | 14.0 | +1.5 | 19.0 | +2.0 |

700 | +7.0 | 16.0 | +1.7 | 21.0 | +2.2 |

HTPO tube performance indicators:

The toughness of HTPO pipe is better than that of ordinary PE pipe, and the elongation at break is higher than 500%.

The embrittlement temperature of HTPO pipes is very low. General plastic pipe, in low temperature environment, its flexibility will become poor. The high temperature resistant lined pipe still has sufficient flexibility and impact resistance at lower ambient temperature.

The HTPO pipe has excellent resistance to slow crack growth. Even if there is occasional external damage during the construction process, the crack growth rate is only a few tenths of that of ordinary PE pipes, which can effectively ensure the normal operation of the pipes.

Physical and mechanical properties of HTPO pipes

Performance | Unit | Experiment method | Numerical value |

Thermal Conductivity(60℃) | W/m.k | DIN 52612-1 | 0.4 |

Thermal expansion coefficient | 10-4/k | DIN 53752-A(20℃-70℃) | 1.8 |

Tensile yield strength | MPa | ISO 527-2 | 20.6 |

Elongation at break | % | ISO 527-2 | 500 |

Elastic Modulus | MPa | ISO 527-2 | 650 |

Performance indicators of HBPE pipes

Anti-permeability of HBPE pipes

Material | Permeability coefficient cm3·cm/cm2·s·Pa |

| 1.777×10-13 |

1.588×10-13 | |

1.587×10-13 | |

HBPE | 4.055×10-17 |

4.462×10-17 | |

4.069×10-17 |

Physical and mechanical properties of HBPE pipes

Performance | Unit | Experiment method | Numerical value |

Thermal Conductivity(60℃) | W/m.k | DIN 52612-1 | 0.4 |

Thermal expansion coefficient | 10-4/k | DIN 53752-A(20℃-70℃) | 1.8 |

Tensile yield strength | MPa | ISO 527-2 | 20 |

Elongation at break | % | ISO 527-2 | 500 |

Elastic Modulus | MPa | ISO 527-2 | 650 |

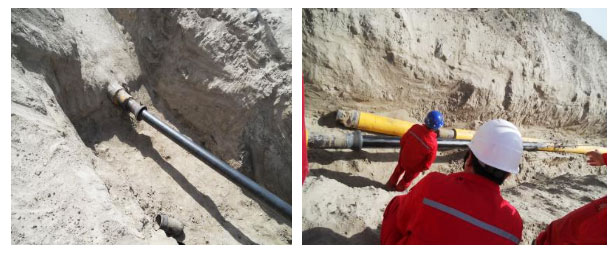

Oilfield: Oil, gas, oil and gas mixed transportation, and sewage pipelines in oilfields have been facing the problem of corrosion and perforation for many years. The anticorrosion and repair process of PE pipes lined with pipelines has the advantages of small investment, short construction period, good anticorrosion effect, and pipeline life. Long and other advantages.

Municipal gas: Because the transmission pressure of natural gas is higher than that of gas, the cast iron pipe (socket connection) used to transport gas can be lined with PE pipe to improve the pressure resistance level of the cast iron pipe, prevent leakage, and meet the requirements of natural gas transmission.

Wechat QR code

Wechat QR code

Home

Home Tel

Tel Product

Product