Category:Municipal plumbing

Introduction:

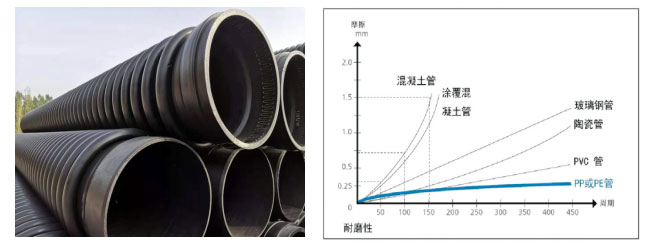

High-density polyethylene (HDPE) and double-wall corrugated pipes are made by two-layer composite co-extrusion molding process.It has the characteristics of high strength, light weight, corrosion resistance and long life. It is an alternative product for traditional drainage and sewage pipes, and it is a key national promotion product. Product implementation standard GB/T19472.1-2004.PE double wall corrugated pipe:

High-density polyethylene (HDPE) and double-wall corrugated pipes are made by two-layer composite co-extrusion molding process. . It has the characteristics of high strength, light weight and long life. It is an alternative product for traditional drainage and sewage pipes, and it is a key product promoted by the state. Product implementation standard GB/T19472.1-2004.

Product Features

* The annular corrugated structure has excellent mechanical properties with both rigidity and flexibility, high strength, compression resistance, bending resistance and impact resistance

* The inner wall is smooth, the fluid friction resistance is small, the book flow is large, no scaling, resistant to cable sheathing, good electrical insulation performance and flame retardancy, durable, reliable cable line operation

* The connection is convenient and reliable, usually with a sealing ring socket link

* Stable chemical properties, corrosion resistance, non-toxic, non-polluting, outstanding performance

* Hollow rib structure, light weight, convenient construction, greatly reduce construction costs

* Wide operating temperature range, -30℃~+60℃

* With a certain flexibility, it is suitable for uneven soil settlement, and with appropriate deflection, the pipe can be directly laid in the slightly curved groove without pipe fittings

* The service life can reach more than 50 years

* Recyclable, save resources for the country and protect the environment.

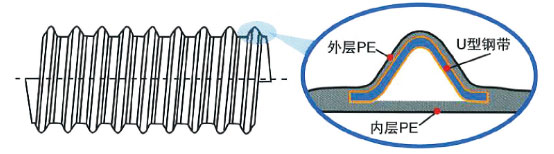

Steel strip reinforced PE spiral corrugated pipe

PE steel belt reinforced spiral corrugated pipe is a double-wall corrugated pipe with high density polyethylene as the matrix, and the steel belt coated with adhesive resin on the surface is formed into a corrugated shape as the main support structure, and wrapped with polyethylene material to form a whole double-wall corrugated pipe. Due to the use of U-shaped steel belt composite PE material, the ring stiffness of the pipe is greatly improved without increasing the cost, and the strength of the coiled pipe is greatly improved under the same weight, which can solve a series of problems such as heavy load. The advantages of large-diameter pipes more obvious. At present, the company can produce pipes with diameters from DN300 to DN2400mm, and the ring stiffness is maintained at 8KN/m2, and can provide similar pipes with ring stiffness of 10KN/m2 and 12.5KN/m2, and the heavy-duty performance can be further improved. Tubes are lighter and stronger. This product can save material costs, and can significantly reduce costs compared with all-plastic buried drainage pipes with the same diameter and ring stiffness. The combination of steel and plastic uses a unique bonding material, and each layer is firm and very reliable in the molten state. In terms of pipe construction, it has long service life, flexibility and shock resistance, light weight, and convenient and quick construction.

The surface of the steel strip is specially pretreated to enhance the anti-corrosion ability of the steel and the adhesion between the steel and the plastic, improve the peeling strength, and wrap it when the plastic raw material is fully melted. Due to the use of special materials and processes to solve the anti-corrosion problem of steel plates, and also to solve the adhesion between steel and PE materials, the service life of the pipeline is the same as that of pure plastic pipes, and the service life can be more than 50 years.

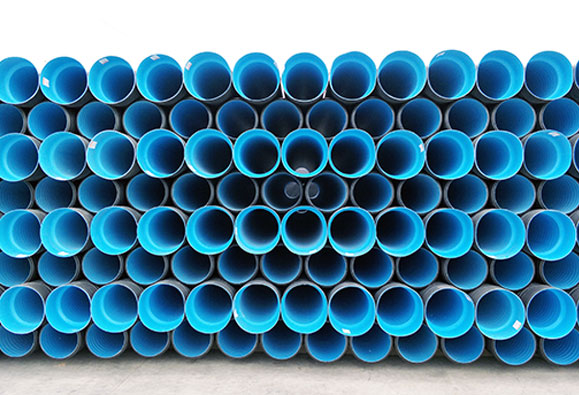

Carat tube (PE structure wall thermal wound tube)

The full name of the carat tube is the high-density polyethylene structure wall thermal winding tube. It is a special-shaped structure wall tube made by the spiral winding process with a smooth inner wall and a spiral reinforcement rib on the outer wall. It is a flexible tube. The carat tube is made of high-density polyethylene as raw material. It is made by winding molding process in the hot melt state, and is cooled by rolling air cooling before the state is not demolded, and the pipe gradually dissipates heat for production. The wall of the pipe is uniform, and the carat pipe adopts the socket-type electrofusion connection. The two ends of the pipe are processed into sockets and sockets during the production process, and the electric fuse is embedded at the socket end. The power supply can complete the welding, which can make the pipeline system achieve zero leakage. The pipe is widely used in urban drainage, municipal drainage, electric power and petrochemical and other fields, and is an ideal substitute for reinforced concrete and cast iron pipes.

Lile Pipe Co., Ltd. has introduced international advanced equipment and technology. The production process uses polyethylene (PE100) as the main raw material, and polypropylene (PP) corrugated pipe as the auxiliary support pipe, which is thermally wound and formed. The high-density polyethylene thermally wound pipe is a flexible pipe, and its structure design is reasonable and the production process is novel. Products can be divided into PR, SQ, VW three series. The company can provide customers with pipes with an inner diameter of DN300-3000mm and a standard length of 6 meters. This product meets the standard requirements of the European standard PrEn-13476 and the national standard GB/19472.2-2004.

High density polyethylene HDPE double-wall corrugated pipe unit: mm

| Nominal outside diameter DN/ID | Minimum average inner diameter | Minimum laminated wall thickness | Minimum inner wall thickness |

200 | ≥ 195 | ≥ 1.5 | ≥ 1.1 |

225 | ≥ 220 | ≥ 1.7 | ≥ 1.4 |

300 | ≥ 294 | ≥ 2.0 | ≥ 1.7 |

400 | ≥ 392 | ≥ 2.5 | ≥ 2.3 |

500 | ≥ 490 | ≥ 3.0 | ≥ 3.0 |

600 | ≥ 588 | ≥ 3.5 | ≥ 3.5 |

800 | ≥ 785 | ≥ 4.5 | ≥ 4.5 |

Physical and mechanical properties (high density polyethylene HDPE double-wall corrugated pipe)

| Project | Requirements | |

Ring stiffness | SN 4 ≥ 4 KN/m2 | SN 8 ≥ 8 KN/m2 |

Impact strength | TIR ≤ 10% | |

Ring flexibility | The specimen is smooth, without reverse bending, rupture and separation of two walls | |

Oven test | No bubbles, no delamination, no cracking | |

Creep rate | ≤ 4 | |

The electric melting tape used for electric melting connection shall be supplied by the pipe manufacturer. The appearance of electric heating melt belt should be flat, and the embedding of electric heating network should be smooth, uniform, without wrinkles and serious warpage affecting use; The base material of electrothermal melting belt is polyethylene, and its material should meet the requirements of material characteristics; The electric heating element in the middle should adopt the electric heating network with nickel and chromium as the main component, and the electric heating network should have no short circuit or open circuit, and the resistance value should not be more than 20Q. The strength of electric melting belt should be adopted according to the current national corresponding product standards. The appearance of heat shrinkable sleeve (belt) connected by hot melt should be flat and free of bubbles, slag inclusion or cracks; The electric heating element of socket electric melting connection should be made of brass wire material, and the surface should be smooth, without cracks, peeling and fracture; Folded electric heating elements should be pre-installed on the inner surface of the socket end and installed firmly. The welding material used for welding connection shall be polyethylene material and welded by welding equipment. Metal materials used in mechanical connection should be treated with anticorrosion and rust prevention, and their material requirements should conform to the current national standards.

Municipal engineering: used as drainage, sewage pipe.

Construction: used as building rain pipe, underground drain pipe, sewage pipe, ventilation pipe, etc.

Industry: widely used in chemical industry, hospital and other industries sewage pipe.

Road engineering: used as seepage and drainage pipe of railway and expressway.

Mine: used as mine ventilation, air supply, drainage pipe.

Railway, highway communication: used as communication cable, cable protection tube.

Agriculture, garden engineering: for farmland, fruit and tea garden, and forest drainage and irrigation.

Open double wall bellows: can be used as saline - alkali highway seepage pipe.

Golf course, football field engineering: used for golf course, football field seepage drain pipe.

Wechat QR code

Wechat QR code

Home

Home Tel

Tel Product

Product