Category:Municipal plumbing

Introduction:

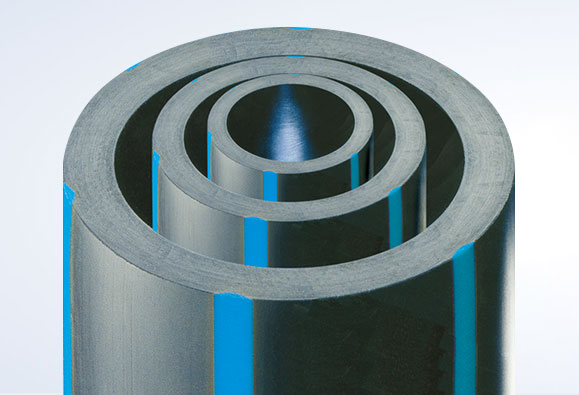

This pipeline product uses PE polyethylene resin as the main raw material, and is processed by extrusion, sizing, spray cooling, cutting and other processes; the PE water supply pipe has good flexibility, strong corrosion resistance, light weight, and excellent impact resistance. Features. Pipes and pipe fittings can be connected by hot-melt sockets, hot-melt butt joints, and electrofusion, etc., so that pipes and pipe fittings are fused together, the system is reliable, the construction cost is low, and it develops rapidly in engineering applications.This pipeline product uses PE polyethylene resin as the main raw material, and is processed by extrusion, sizing, spray cooling, cutting and other processes; PE water supply pipe has good flexibility, strong corrosion resistance, light weight, and excellent impact resistance. Features. Pipes and pipe fittings can be connected by hot-melt sockets, hot-melt butt joints, and electrofusion, etc., so that pipes and pipe fittings are fused together, the system is reliable, the construction cost is low, and it develops rapidly in engineering applications.

Polyethylene is an inert material, resistant to a variety of chemicals, not easy to breed bacteria, light weight, low resistance to water flow, easy and quick installation, low cost, long life, thermal insulation, etc. The performance is better than that of steel pipe and cast iron pipe. PE100 water supply pipe is used in the conveying system of drinking water, and the hygienic and safety performance of the product meets the requirements of the former Ministry of Health's "Standard for Hygienic and Safety Evaluation of Drinking Water Transmission and Distribution Equipment and Protective Materials" (2001).

The corrosion resistance of polyethylene pipes makes them suitable for transporting some corrosive liquids such as acids and alkalis, and can be installed in corrosive environments such as swamps and humidity. Polyethylene pipes have good flexibility, and the pipes can be easily laid along the trench terrain, avoiding obstacles during the laying process, and adapting to the settlement of pipe foundations in swampy areas and areas with loose soil. Polyethylene pipe has high impact resistance, so it is not easy to break or damage during installation. The pipes can be connected by hot melt and electrofusion, which can ensure the strength of the interface and avoid leakage.

| Unit:mm | ||||

Nominal outer diameter | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

Nominal pressurePN, MPa | |||||

0.6 | 0.8 | 10 | 1.25 | 1.6 | |

Nominal wall thickness | Nominal wall thickness | Nominal wall thickness | Nominal wall thickness | Nominal wall thickness | |

32 |

|

|

|

| 3.0 |

40 |

|

|

|

| 3.7 |

50 |

|

|

|

| 4.6 |

63 |

|

|

| 4.7 | 5.8 |

75 |

|

| 4.5 | 5.6 | 6.8 |

90 |

| 4.3 | 5.4 | 6.7 | 8.2 |

110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

140 | 5,4 | 6.7 | 8.3 | 10.3 | 12.7 |

160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

355 | 13,6 | 16.9 | 21.1 | 26.1 | 32.2 |

400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

710 | 27.2 | 33.9 | 42.1 | 52.2 |

|

800 | 30.6 | 38.1 | 47.4 | 58.8 |

|

900 | 34.4 | 42.9 | 53.3 |

|

|

1000 | 38.2 | 47.7 | 59.3 |

|

|

Pipe fittings series

Injection pipe fittings are produced in accordance with GB/T13663.3-2018 standard, with complete varieties and specifications.

It is suitable for connection forms such as hot flame butt, electrofusion welding and flange connection.

Socket injection molding pipe fittings are produced in accordance with GB/T13663.3-2005 standard, with complete varieties and specifications.

It is suitable for the connection of smaller diameter pipes such as hot-melt socket, steel-plastic transition thread connection and flange connection.

Properties of PE100 Pipe

| Serial number | Project | Requirements | |

1 | 20 basketry hydrostatic strength (circumferential stress 12.4 MPa.100h) | No rupture, no leakage | |

2 | 80P hydrostatic strength (circumferential stress 5.5 MPa, 165h) | No rupture, no leakage | |

3 | 80P hydrostatic strength (circumferential stress 5.0 MPa, 1000h) | No rupture, no leakage | |

4 | Elongation at break,% | ≥ 350 | |

5 | Longitudinal shrinkage (11CTC),% | ≤ 3 | |

6 | Oxidation induction time (200P), min | ≥ 20 | |

7 | Weathering resistance "(after the pipe has received aging energy ≥ 3.5 GJ/m2) | Hydrostatic strength at 80 ℃ (circumferential stress 5.5 MPa, 165h) | No rupture, no leakage |

Elongation at break,% | ≥ 350 | ||

Oxidation induction time (200 'C), min | ≥ 10 | ||

Note: Only applicable to blue pipe | |||

Corrosion resistance table of PE pipe

| Medium | Concentration | PE- | Medium | Concentration | P | - | |

20 ℃ | 60 ℃ | 20 ℃ | 60 ℃ | ||||

Hydrochloric acid | 10% | S | S | Potassium permanganate | 20% | S | S |

Concentrate | S | S | Potassium hypochlorite | Unsaturated | S | S | |

Sulfuric acid | 10% | S | S | Sodium hypochlorite | 15% | S | S |

50% | S | S | Ferric chloride (11) (111) | Saturation | S | S | |

98% | S | NS | Saturation | S | S | ||

Fog | NS | NS | Seawater | -- | NS | S | |

Nitric acid | 25% | S | S | Formaldehyde | 40% | S | S |

50% | L | NS | Carbon tetrachloride | 100% | S | NS | |

75% | NS | NS | Methanol | 100% | S | S | |

100% | NS | NS | Glucose | Saturation | L | S | |

Hydrogen desert acid | 50% | S | S | Gasoline, petroleum (aliphatic carbon compound) | 100% | S | L |

100% | S | S | |||||

Formic acid | 50% | S | S | Hydrogen peroxide | 30% | - | S |

98-100% | S | S | Hydrogen peroxide | 90% | S | NS | |

Benzoic acid | Unsaturated | S | S | Acetone | 100% | L | L |

Oxalic acid | Saturation | S | S | Acetaldehyde | 100% | S | L |

Calcium hydroxide | Saturation | S | S | Benzaldehyde | 100% | S | L |

Sodium hydroxide | 40% | S | S | Benzene | 100% | L | L |

Unsaturated | S | S | Dioctyl phthalate | 100% | S | S | |

Hydrogen oxidation | Saturation | S | S | Oxalic acid | 100% | S | S |

Ammonia (liquid) | 100% | S | S | Ethanol | 40% | S | L |

Ammonia (aqueous solution) | Dilution | S | S | Cycloethyl ketone | 100% | S | L |

Note:S: corrosion resistance L: limited corrosion resistance NS: non-corrosion resistance saturation: 20 ℃ saturated aqueous solution; Dilution: Diluted aqueous solution with concentration not higher than 10%; Unsaturated: Unsaturated aqueous solution with a concentration of more than 10%; Industrial grade: industrial grade aqueous solution

The service life of polyethylene pipes is more than 50 years, which has not only been confirmed by international standards and some advanced foreign standards, but also proved by practice. PE water supply pipes are widely used in municipal water supply systems, building water supply systems, residential quarters, factory buried water supply systems, industrial and water treatment pipeline systems due to their excellent performance.

Wechat QR code

Wechat QR code

Home

Home Tel

Tel Product

Product