Category:Municipal plumbing

Introduction:

The PVC-U water supply pipes produced by our company are defined as Unplasticized Polyvinly Chloride in the ISO standard. Only necessary additives are allowed, no plasticizers, hence the name. PVC-U pipes for water supply use PVC resin as the main raw material, add appropriate amount of additives, and are processed and formed by mixing, extruding, sizing, cooling, cutting and expanding. The injection-molded pipe fittings are made of PVC resin as the main raw material, add appropriate amount of additives, and are uniformly mixed and then injection-molded. The products have been tested by authoritative departments such as the National Plastic Products Quality Supervision and Inspection Center, the National Building Materials Testing Center, and the Hebei Provincial Health and Epidemic Prevention Station, and fully meet the requirements of relevant national standards and enterprise standard...The PVC-U water supply pipes produced by our company are defined as Unplasticized Polyvinly Chloride in the ISO standard. Only necessary additives are allowed, no plasticizers, hence the name. PVC-U pipes for water supply use PVC resin as the main raw material, add appropriate amount of additives, and are processed and formed by mixing, extruding, sizing, cooling, cutting and expanding. The injection-molded pipe fittings are made of PVC resin as the main raw material, add appropriate amount of additives, and are uniformly mixed and then injection-molded. The products have been tested by authoritative departments such as the National Plastic Products Quality Supervision and Inspection Center, the National Building Materials Testing Center, and the Hebei Provincial Health and Epidemic Prevention Station, and fully meet the requirements of relevant national standards and enterprise standards. Executive standard: GB/T10002.1-2006; GB/T10002.2-2003;

Product Features:

1. Hygiene

The green lead-free stabilization system is adopted, which is hygienic and non-toxic, does not scale or breed microorganisms such as algae during use, and the water quality is not subject to secondary pollution.

2. Light weight

The weight per unit length is 1/5 of the cast iron pipe and 1/4 of the ductile iron pipe, which is convenient for installation and transportation.

3. Easy to install

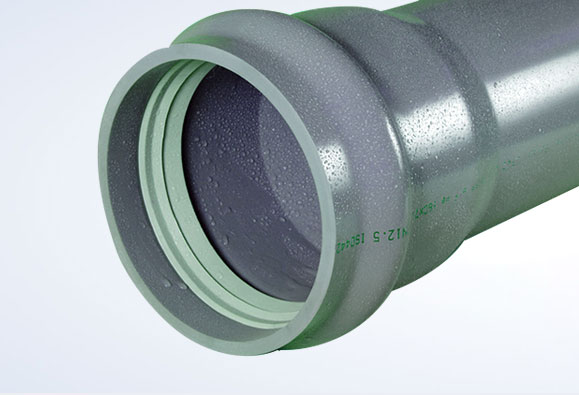

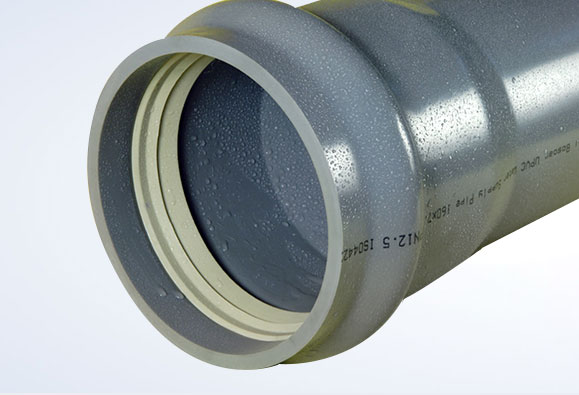

Adopt glue connection and rubber sealing ring connection, easy installation and reliable sealing.

4. Low cost

The transportation, installation and material costs are low, and the total construction cost of the project is 30-40% lower than that of cast iron pipes, which is also much lower than that of similar plastic pipes.

5. Long life

Under normal working pressure, the service life can reach more than 50 years.

6. High strength

The tensile strength at room temperature is not less than 45MPa.

7. Low resistance

The inner wall is smooth, the fluid medium resistance is small, no blockage, and the head loss is more than 25% lower than that of cast iron pipes.

8. Corrosion resistance

It has good acid resistance, alkali resistance and corrosion resistance, and there will be no pitting corrosion during use.

9, heat insulation, flame retardant

The thermal conductivity of PVC-U pipe is lower than that of traditional pipe, and it is self-extinguishing and difficult to burn.

Nominal pressure grade and size of pipe: Unit: mm | ||||||||||||

Nominal diameter | 0.63MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa | 2.5MPa | ||||||

Wall thickness | Tolerance | Wall thickness | Tolerance | Wall thickness | Tolerance | Wall thickness | Tolerance | Wall thickness | Tolerance | Wall thickness | Tolerance | |

20 |

|

|

|

|

|

|

|

|

|

| 2.3 | +0.6 |

25 |

|

|

|

|

|

|

|

| 2.0 | +0.4 | 2.8 | +0,5 |

32 |

|

|

|

|

|

| 2.0 | +0.4 | 2.4 | +0.5 | 3,6 | +0.6 |

40 |

|

|

|

| 2.0 | +0.4 | 2.4 | +0.5 | 3.0 | +0,5 | 4.5 | +0,7 |

50 |

|

| 2.0 | +0.4 | 2.4 | +0.5 | 3.0 | +0.5 | 3.7 | +0.6 | 5.6 | +0.9 |

63 | 2.0 | +0.4 | 2.5 | +0.5 | 3.0 | +0.5 | 3.8 | +0.6 | 4.7 | +0.8 | 7.1 | +1.1 |

75 | 2.3 | +0.5 | 2.9 | +0.5 | 3.6 | +0.6 | 4.5 | +0.7 | 5.6 | +0.9 | 8.4 | +1.3 |

90 | 2.8 | +0.5 | 3.5 | +0.6 | 4.3 | +0.7 | 5.4 | +0.9 | 6.7 | +1.1 | 10.1 | +1.6 |

110 | 2.7 | +0,5 | 3.4 | +0.6 | 4.2 | +0.7 | 5,3 | +0.8 | 6.6 | +1.0 | 10.0 | +1.5 |

125 | 3.1 | +0.6 | 3.9 | +0.6 | 4.8 | +0.8 | 6.0 | +0.9 | 7.4 | +1,2 | 11.4 | +1.8 |

140 | 3.5 | +0.6 | 4.3 | +0.7 | 5.4 | +0.9 | 6.7 | +1.1 | 8.3 | +1.3 | 12.7 | +2.0 |

160 | 4,0 | +0.6 | 4.9 | +0.8 | 6.2 | +1.0 | 7.7 | +1.2 | 9.5 | +1.5 | 14.6 | +2.2 |

180 | 4.4 | +0.7 | 5.5 | +0.9 | 6.9 | +1.1 | 8.6 | +1.3 | 10.7 | +1.7 | 16.4 | +2.5 |

200 | 4.9 | +0.8 | 6.2 | +1.0 | 7.7 | +1.2 | 9.6 | +1.5 | 11.9 | +1.8 | 18.2 | +2.8 |

225 | 5.5 | +0.9 | 6.9 | +1.1 | 8.6 | +1.3 | 10.8 | +1.7 | 13.4 | +2.1 |

|

|

250 | 6.2 | +1.0 | 7.7 | +1.2 | 9.6 | +1.5 | 11.9 | +1.8 | 14.8 | +2.3 |

|

|

280 | 6.9 | +1.1 | 8.6 | +1.3 | 10.7 | +1.7 | 13.4 | +2.1 | 16.6 | +2.5 |

|

|

315 | 7.7 | +1.2 | 9.7 | +1.5 | 12.1 | +1.9 | 15.0 | +2.3 | 18.7 | +2.9 |

|

|

355 | 8.7 | +1.4 | 10.9 | +1.7 | 13.6 | +2.1 | 16.9 | +2.6 | 21.1 | +3.2 |

|

|

400 | 9.8 | +1,5 | 12.3 | +1.9 | 15.3 | +2.3 | 19.1 | +2.9 | 23.7 | +3.6 |

|

|

450 | 11.0 | +1.7 | 13.8 | +2.1 | 17.2 | +2.6 | 21,5 | +3.3 | 26.7 | +4.1 |

|

|

500 | 12.3 | +1.9 | 15.3 | +2.3 | 19.1 | +2.9 | 23.9 | +3.6 | 29.7 | +4.5 |

|

|

560 | 13.7 | +2.1 | 17.2 | +2.6 | 21.4 | +3.3 | 26.7 | +4.1 |

|

|

|

|

630 | 15.4 | +2.4 | 19.3 | +2.9 | 24.1 | +3.7 | 30.0 | +4.5 |

|

|

|

|

710 | 17.4 | +2.7 | 21.8 | +3.3 | 27.2 | +4.1 |

|

|

|

|

|

|

800 | 19.6 | +3.0 | 24.5 | +3.7 | 30.6 | +4.6 |

|

|

|

|

|

|

900 | 22.0 | +3.4 | 27.6 | +4.2 |

|

|

|

|

|

|

|

|

1000 | 24.5 | +3.7 | 30.6 | +46 |

|

|

|

|

|

|

|

|

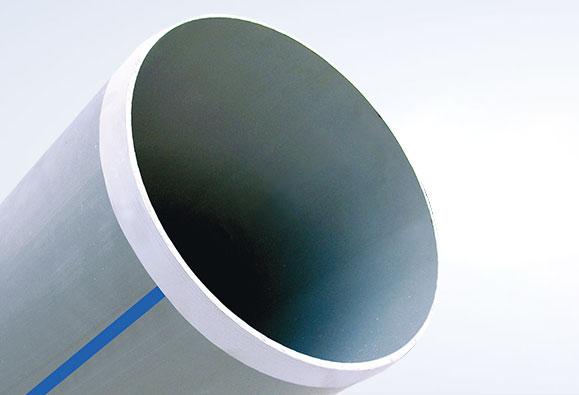

1. Appearance

The inner and outer surfaces of the pipe should be smooth, without obvious scratches, dents, visible impurities and other surface defects that affect the performance of the pipe. The end face of the pipe should be cut flat and perpendicular to the axis.

2. Opaqueness

The tubing should be opaque.

3. Length

The overall length of the pipe is generally 4 meters, 5 meters, and 6 meters, which can also be determined through negotiation between the supply and demand sides.

4. Color

PVC-U water supply pipes are generally gray, and other colors can also be produced through negotiation between the supplier and the buyer.

5. Physical and mechanical properties

Project | Technical index | Test method |

Softening temperature of micro-card | ≥ 80 ℃ | According to "GB/T10002.1-2006" standard |

Longitudinal retraction rate | ≤ 5% | |

Dichloromethane impregnation experiment | At 15 ℃ and 15min, the surface change should not be inferior to that of 4N | |

Drop hammer impact test (0 ℃) TIR | ≤ 5% | |

Hydraulic test | No rupture, no leakage | |

Connection sealing test | No rupture, no leakage |

6. Hygienic performance

The hygienic performance of pipes and fittings complies with the Health and Safety Evaluation Specifications for Drinking Water Transmission and Distribution Equipment and Protective Materials of the Ministry of Health.

PVC-U injection molding pipe fittings for water supply

1. Color

It is generally gray, and other colors can also be produced through negotiation between the supplier and the buyer.

2. Appearance

The surface of the pipe fittings should be smooth, and no defects such as cracks, bubbles, peeling, severe cold spots, obvious impurities, uneven color, decomposition and discoloration are allowed.

3. Physical and mechanical properties

Project

| Require | ||||

Microcard softening temperature | ≥74℃ | ||||

Oven experiment | Comply with GB/T8803-2001 | ||||

Drop test | No rupture | ||||

Hydraulic test | Nominal outer diameter/dn | Test temperature/℃ | Test pressure/MPa | Experiment time/h | Experimental requirements |

dn≤90mm | 20 | 4.2×PN | 1 | No rupture | |

3.2×PN | 1000 | ||||

dn>90mm | 20 | 3.36×PN | 1 | ||

2.56×PN | 1000 | ||||

Auxiliary accessories

Physical properties of rubber seal

Project | Indicators | Note |

Shore hardness | 45-55degree | Health indicator complianceGB/T17219 |

Elongation | ≥500% | |

Tensile strength | ≥16MPa | |

Deformation | ≤20% | |

Aging factor | ≥0.8(70°,144h) |

2. Performance index of adhesive

Project | Indicators | Requirements |

Viscosity | 100-110 centipoise | Hygienic indexes conform to GB/T17219, and the shear strength of bonded places is ≥ 5 MPa |

Chroma | < 1 ° | |

Residual chlor-alkali content | < 0.7 mg/L | |

Volatile acids | < 0.005 mg/L | |

Solid content | 11.9%-12% | |

Turbidity | < 0.5 ° | |

Cyanide | Not to be detected | |

Potassium permanganate consumption | < 1mg/L | |

Taste | No peculiar smell |

PVC-U water supply pipe installation procedure

R-R elastic sealing rubber ring connection installation procedure:

1. Wipe the inner surface of the socket groove and the outer surface of the socket with a veil;

2. Put the outskirts in the socket groove in the correct way (the big end is inward, the small end is outward);

3. Draw the insertion depth mark on the socket end;

4. Apply lubricant to the broker and the socket; (oil is prohibited)

5. Use the wire tensioner or the lever hoist to pull it in place at one time;

6. Use a feeler gauge to check whether the rubber ring is normal along the circumference.

T-S method pipeline connection steps:

1. Cutting - cut the pipe evenly and vertically according to the required size, and then chamfer;

2. Cleaning - clean the dust or grease on the surface of the socket and the inner surface of the socket;

3. Spreading - spread the adhesive evenly and quickly on the outer surface of the socket and the inner surface of the socket;

4. Insertion - Align the center line of the two pipes or pipes and fittings, insert them quickly and rotate 1/4 turn to make the adhesive evenly distribute the gap between the socket and the socket;

5. Keep - keep it still after the insertion is completed to allow the adhesive to solidify, keep it for at least one minute, and finally wipe off the excess adhesive outside the tube;

6. End - After the connection is completed, avoid applying load to the pipe for ten minutes.

PVC-U pipes can be widely used in water transmission and distribution projects where the water temperature is not higher than 45 °C, and are widely used in the following fields:

>>Urban Water Supply Project

>>Agricultural water-saving irrigation, low-pressure irrigation projects

>>Water supply project in water source

>>Industrial production pipe network

>>mine

>>Residential quarters, residential upstairs water projects

Wechat QR code

Wechat QR code

Home

Home Tel

Tel Product

Product